News classification

Contact us

- Add: ChanFu Dong Road,XiaoBian Village, ChangAn Town,DongGuan City,GuangDong,China

- Tel: +8613652508770(Jerry )

- Fax: 0769-23094426

- Email: [email protected]

Where are spring loaded pins generally used?

Where are spring loaded pins generally used?

Spring loaded pins, also known as probes, spring contact pins or Pogo Pins, are simple but powerful connection devices. They are widely used in devices that require frequent contact, plugging and unplugging, electrical connection or signal transmission. With its good conductivity, wear resistance and repeatable plugging and unplugging characteristics, spring loaded pin have become an indispensable component of many high-end electronic products.

Cnomax will systematically introduce the working principle, core advantages and applications of spring loaded pin in various scenarios, and comprehensively explain the key role of spring pins in modern industry, medical care, consumer electronics and other industries.

1. Structure and working principle of spring loaded pin

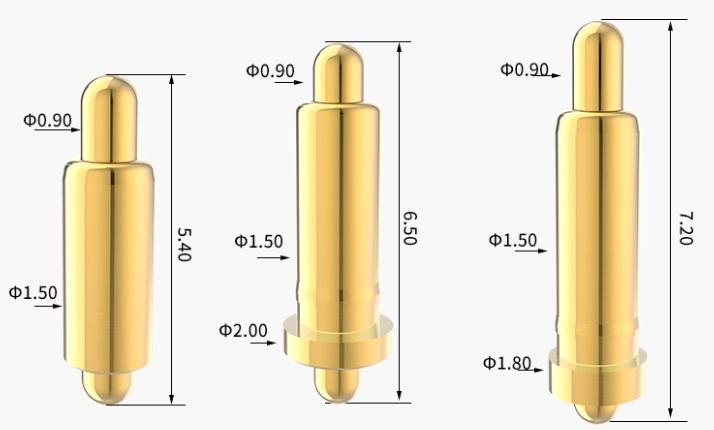

The typical structure of a spring pin includes three main parts:

1. Plunger: The part that contacts the contact surface of the object under test or the target, usually with a round, pointed or other special-shaped design, used to improve contact stability.

2. Barrel: The outer shell part, which plays a guiding and supporting role.

3. Spring: The built-in spring is used to provide an outward elastic force to make the needle closely contact the target and improve conductivity.

When working, when the needle of the spring pin is pressed into the needle tube by external pressure, the built-in spring is compressed. After the pressure is released, the spring returns to its original state and pushes the needle back. The whole process can be repeated thousands of times without affecting its contact performance.

2. Main application areas of spring pins

1. Consumer electronics

Spring pins are most commonly used in the consumer electronics industry, especially in the following aspects:

a. Charging interface

Smart watches, Bluetooth headsets, portable players and other devices usually use spring pins as charging connection contacts. It has the following advantages:

Can be blind plugged to improve user experience;

Small size, suitable for micro devices;

Support magnetic docking to achieve non-directional plugging and unplugging;

Wear-resistant and corrosion-resistant, supporting more than thousands of plugging and unplugging.

b. Wearable devices

Due to the requirements of small space and light weight, smart bracelets, smart glasses and other products also prefer to use spring pins as data synchronization or power interfaces.

c. Mobile phone accessories

Some mobile phone cases and modular peripherals (such as magnetic keyboards) use spring pins to connect to the mobile phone body for signal or power, ensuring a light and stable user experience.

2. Automated testing (ATE)

In the field of automated test equipment (ATE, Automated Test Equipment), the application of spring pins is almost everywhere, mainly reflected in:

a. PCB testing

Spring pins are widely used in ICT test fixtures, and they quickly contact the pads or test points on the PCB board through the needle bed to achieve large-scale, fast and reliable circuit testing.

b. Finished product testing (FCT)

In finished product testing, spring pins are used to establish temporary electrical connections without destroying the appearance or structure of the product, and are used to read key parameters such as sensors, voltage, and current.

c. Chip burning/communication verification

Using spring pins to program and communicate with chips such as MCU, EEPROM, Flash, etc. can avoid welding and improve production efficiency.

3. Medical equipment

Medical equipment has extremely high requirements for connectors. They must be safe and reliable, as well as compact and portable. Therefore, spring pins are widely used, mainly including:

a. Wearable medical devices

Such as dynamic electrocardiogram recorders, blood glucose monitors, body temperature recording devices, etc., all rely on spring pins to connect to terminals such as chargers and data acquisition devices.

b. Non-invasive medical monitoring equipment

Contact surface sensors often transmit collected data to the main control system through spring pins and provide necessary power supply interfaces.

c. Portable diagnostic equipment

On instruments such as blood analyzers and portable ultrasound instruments, spring pins are used for modular interfaces, supporting fast disassembly and multiple uses.

4. Industrial automation and robots

The industrial field has a harsh operating environment and extremely high requirements for the stability of connectors. Spring pins are widely used in the following scenarios:

a. Industrial charging pile/AGV automatic recharging interface

Automated guided vehicles (AGVs), smart forklifts, etc. need to automatically dock when charging. Spring pins have a certain degree of flexible travel and environmental resistance, making them ideal electrical interfaces.

b. Modular connection of equipment

Industrial modules, sensors, and IO modules can be quickly connected through spring pins, which is convenient for replacement and maintenance, and improves production flexibility.

c. Industrial detection system

Spring pins can be used to automatically detect the size and electrical performance of mechanical parts, effectively improving detection accuracy and efficiency.

5. Automotive electronic system

The degree of electronicization of modern automobiles is increasing, and spring pins play a role in the following modules:

Battery management system (BMS): used for signal and temperature detection connection of battery packs.

Smart cockpit: used for modular display screens, power supplies or peripheral docking.

ECU testing and diagnosis: During the vehicle debugging stage, spring pins can be used to temporarily access the OBD interface or test port.

Wireless charging module docking: On-board wireless charging modules often use spring pins as output interfaces.

Its high temperature resistance, vibration resistance, and long life are particularly suitable for automotive working environments.

6. Aerospace and military fields

In scenarios such as aerospace and military electronics that require extremely high reliability, spring pin applications include:

Missile system module interface

Flight recorder data access

Electrical connection inside the satellite cabin

Hot-swap interface for military communication equipment modules

These devices often face harsh conditions such as high temperature, low pressure, vibration, and corrosion. Spring pins can provide reliable mechanical and electrical connection performance.

3. Other extended applications of spring pins

a. Antenna interface of wireless communication module

In some RF products, spring pins are used as antenna connection contacts or RF shielding ground wires.

b. Elastic contact components of magnetic connectors

In magnetic connectors, spring pins are key components to ensure multiple plug-in and pull-out and automatic alignment.

c. Education and experimental equipment

Products such as programming development boards for teaching and open source hardware platforms often use spring pins to connect to peripherals, which is convenient for repeated testing and debugging.

4. Future Development Trends

As electronic products tend to be thinner, more efficient and modular, the application of spring pins is also expanding. Possible future development trends include:

Miniaturization and high density: suitable for high-precision microelectronic products (such as wearable chip-level connections).

Integrated signal and power: a single pin can transmit signal and power at the same time, reducing system complexity.

Higher frequency transmission capability: supports RF-level and millimeter wave connections.

Environmentally friendly and durable design: using lead-free materials, high cycle life, and recyclable structure.

Spring pins play a key role in many industries with their unique structure and excellent performance. From smart wearables, medical devices to automotive electronics, industrial automation, to high-end testing and military equipment, it can provide connection solutions with high reliability, electrical stability and mechanical adaptability. Its application scenarios are constantly expanding, and it is an important part of the future development of modular and intelligent device connections.